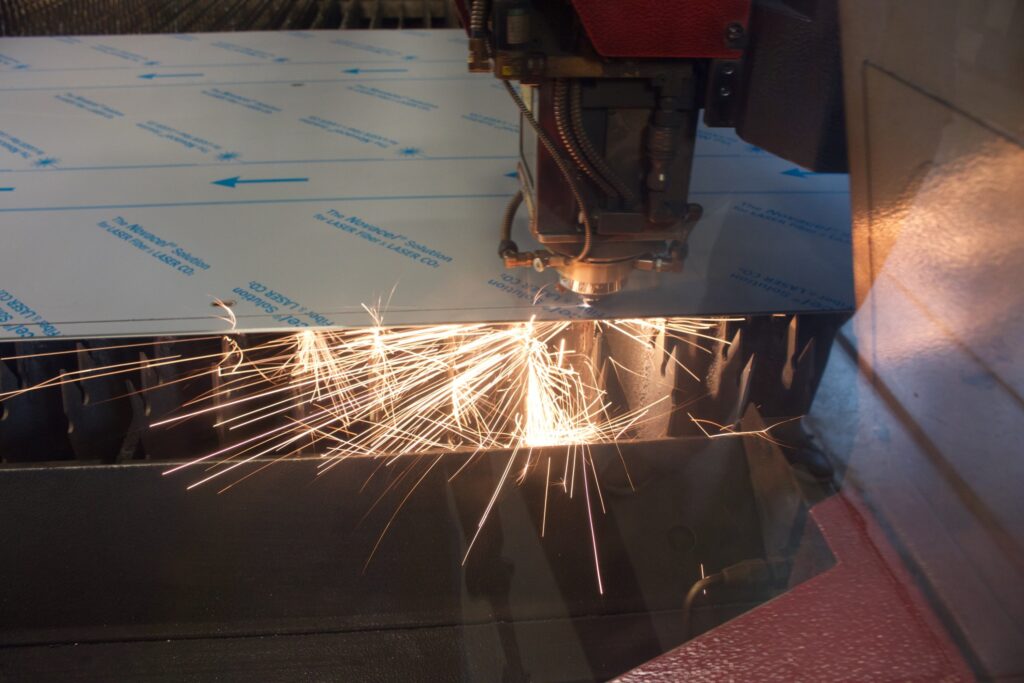

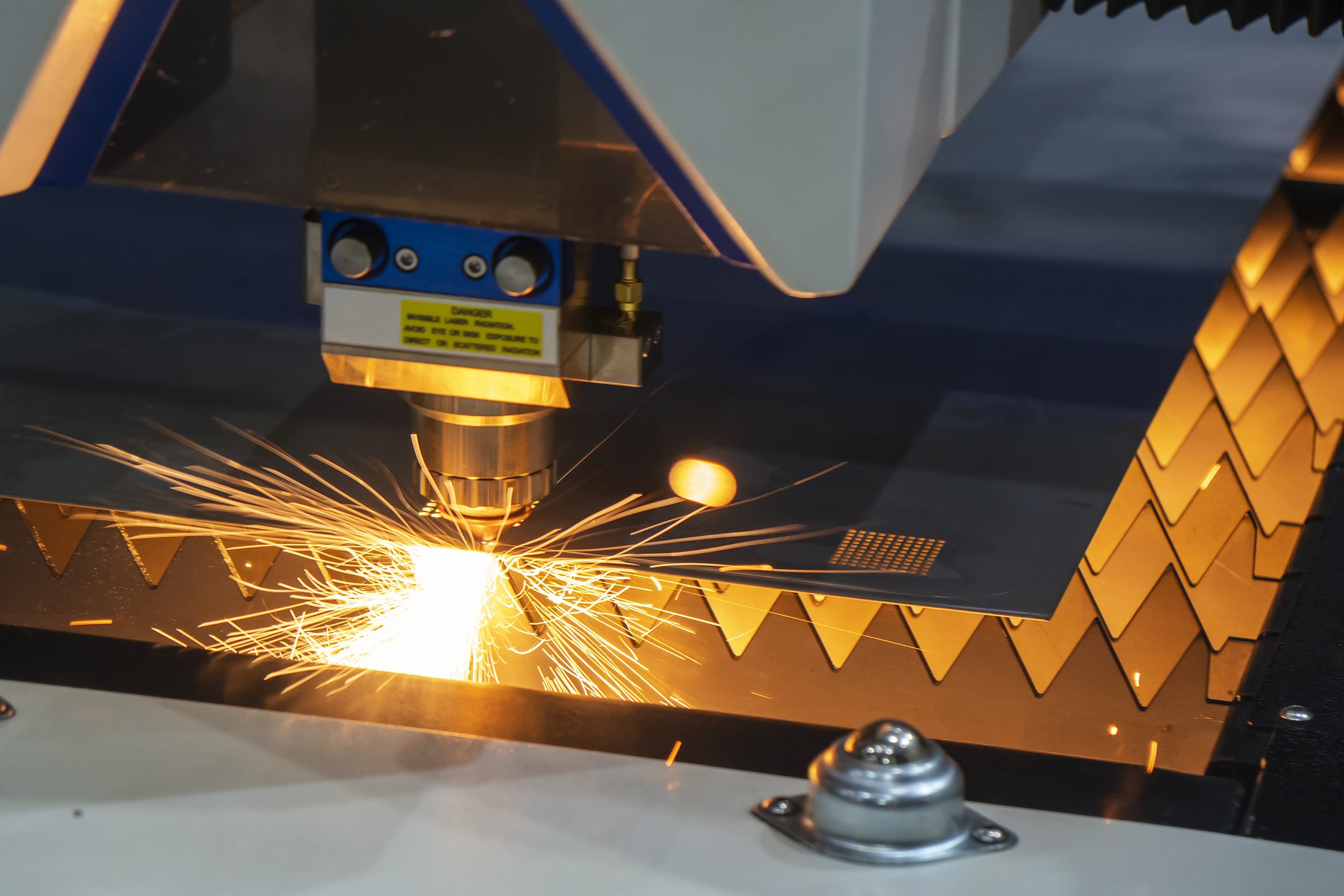

Sheet Metal Laser Cutting Services

Laser cutting gives you the flexibility to choose between making one prototype at the beginning of your project to mass production once you are ready. Lynx Manufacturing's automated laser cutting machines offers you a one-stop manufacturer providing savings for your projects. Laser cutting technology helps reduce lead times and ensures that your products are on-time and within budget. We can offer you a lower cost per part with the end product being the quality part you need in order to satisfy and hopefully exceed your customers' expectations. For many years, CO2 laser cutting has been a staple in the fabrication industry and many consider it to be the most reliable option. However, more recently the industry has been using fiber laser cutting. The process is similar to CO2 cutting but varies in one important way: the cutting beam width is only 1/10 the width of CO2 laser’s cutting beam. “Briefly, fiber laser light is created by banks of diodes. The light is channeled and amplified through fiber optic cable similar to that used for data transfer. The amplified light, on exiting the fiber cable, is collimated or straightened and then focused by a lens onto the material to be cut.”